POWER QUALITY

As global warming continues to threaten our planet and weather calamities are ever-present, the climate is changing, whether we are ready or not. Luckily, Consumers of Electricity, power and electrical companies are ready for the challenge, as they continue to unveil greener technology and drive the focus towards renewable energy sources. With fresh innovation, come new challenges, particularly as the electric grid becomes increasingly more complicated and modernized.

Nowadays, electrical utilities and consumers are paying much attention to enhance the quality of the generated and distributed electrical energy. The main aims are to produce clean electrical power and to distribute it to the end customers with acceptable power quality performance in a cost-effective manner. Since the importance of power quality aspects has increased due to the booming developments in power-electronic devices and renewable energy resources under the umbrella of smart grids. Besides, the deregulation of the electricity market resulted in a competitive market in which multiple utility companies try to deliver the best products (generated electrical energy) for the customers who have the chance to choose the utility company that provides them with electrical energy with the highest quality level. In consequence, power quality will play an essential role in modern electrical power systems. However, there are also difficulties before wider applicability is possible for the power quality performance limits in reality.

However, Electrical power is certainly the most essential raw material used by any Industry and commercial establishment today and it has become a necessity and a part of our everyday life.

Unluckily Electricity is not a usual commodity because it is required as a continuous flow and it cannot be stored conveniently in quantity and it cannot be subject to quality assurance checks before it is used.

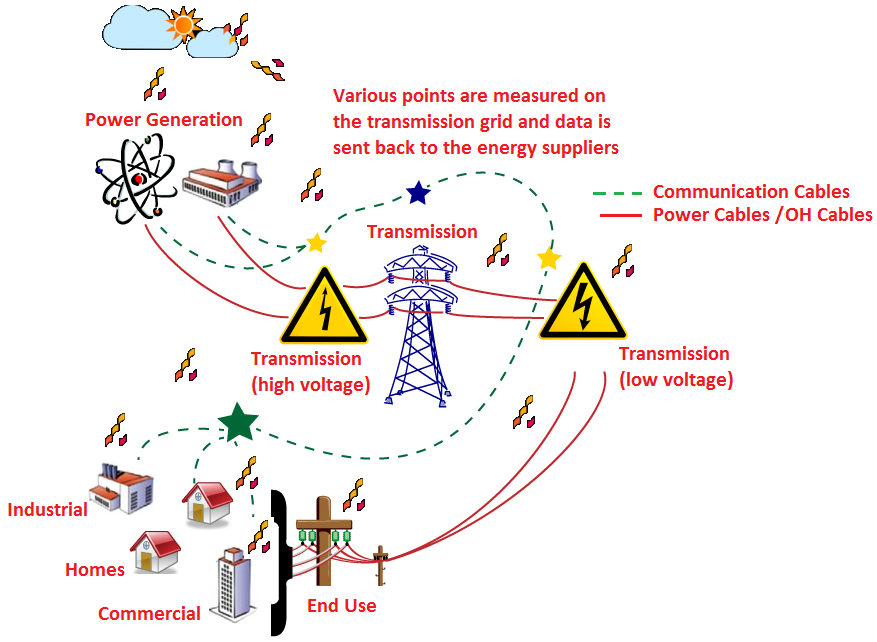

Distribution of Electricity itself is having various difficulties in reality, First is electricity is very different from any other product – it is generated far from the point of use, is fed to the grid together with the output of many other generators and arrives at the point of use via several transformers and many kilometers of overhead and possibly UG Cabling. Where the industry has been privatized, these network assets will be owned, managed and maintained by a number of different organizations. Hence assuring the quality of delivered power at the point of use is no easy task and secondly there is no way that sub-standard electricity can be withdrawn from the supply chain or rejected by the customer.

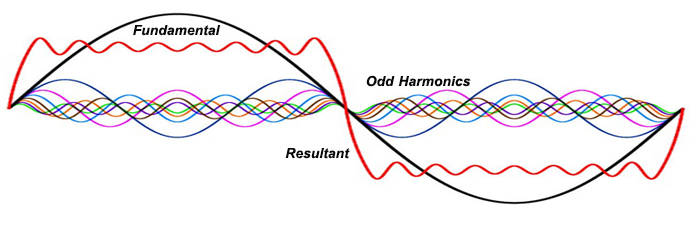

Supplier’s point of serious concern is Harmonics generated by nonlinear load installed at consumer’s place and reduction of efficiency of their line, transformers and increased loss on transmission and distribution. Combining all effective outcomes is premature aging of components and unexpected failure of components and trouble in maintenance apart from the distribution side challenges like Sag, Swell, Interruption and transients, which are all serious consequences to the consumers and distribution company’s assets and subsequent various other losses.

From the consumers’ point of view, the problem is even more difficult. There are some limited statistics available on the quality of delivered power, but the acceptable quality level as perceived by the supplier may be very different from that required or perhaps desired by the consumer. The most obvious power defects are complete interruption (which may last from a few seconds to several hours) and voltage dips or sags where the voltage drops to a lower value for a short duration. Naturally, long power interruptions are a problem for all users during the continuous process if happens rapidly and unexpected. But many operations are very sensitive to even very short interruptions (In milliseconds to minute). For example, Semiconductor industry, where the production of a wafer requires a dozens of processes over several days and the failure of a single process is catastrophic, data centers, where the value of the transaction is high but the cost of processing is low. The inability in transaction end up with big loss to the consumer and even a minute of interruption can lead in to several lacs of loss to the consumer as well as other various clients of that consumer.

Also failure of critical components during the time of process, Server crash, Software corruption, fatal accidents and flashover due to malfunction of protective devices in the industry and Erratic Output of Health Care lifesaving machines and Fire of entire facility.

Many of the issues due to poor power quality may be unnoticed to either the consumers or suppliers

Above said issues are all-little of the examples. However, surprisingly how many apparently mundane operations have quite critical power supply requirements. Examples include large retail units with computerized point of sale and stock control equipment and manufacturing plant with distributed control.

What do we mean by ‘Power Quality’?

A perfect power supply would be one that is first it must be always available and free of disturbance, always within voltage and frequency tolerances, and has a pure noise-free sinusoidal wave shape, which is simply that drives an electrical device and the device’s ability to function properly with that electric power.

Areas of concern

- Continuity of service

- Variation in voltage magnitude

- Transient voltages and currents

- Harmonic content in the waveforms

Issues to affect good Power Quality

- Voltage sags or dips

- Surges

- Swell

- Momentary power interruptions

- Extended power interruptions

- High-speed transients

- Harmonic distortion – Odd, Inter and Even Order

- Supra Harmonics (2 to 150 Khz range )

- Electrical noise

- Rapid Voltage Change (RVC)

- Notches on voltage

- Ground loops

- Lightning damage or lack of preparedness